D1、Industrial automation simulation object

Simulation teaching, also known as simulation teaching, is a kind of teaching method that uses computer to simulate real natural or social phenomena and students play a certain role in skill training. Simulation teaching can make up for the deficiency of objective conditions to a great extent, provide students with a near real training environment and improve their professional skills. "Industrial automation simulation object" is a part of "industrial automation object and controller simulation cosai". It is also an important part of our digital twin. All the real training systems of our company have corresponding virtual systems. Simulation objects include mechanical equipment, electrical system, and the whole virtual factory. Cosai, controller and object simulation for automation in industrial.

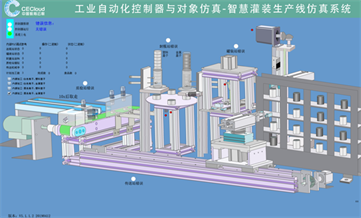

D2、Simulation of industrial automation controller

"Industrial automation controller simulation" is a part of "industrial automation object and controller simulation cosai". It is also an important part of our digital twin. Our company has developed DDC, PID, Siemens all mainstream PLC, 3S CoDeSys PAC controller simulation, or simulation interface. It can realize the docking with our company's small simulation object, process automation simulation object, manufacturing automation simulation object, and factory simulation system. Cosai, controller and object simulation for automation in industrial. "Industrial automation controller simulation" is also an important part of our company's digital twin.

D3、Semi physical simulation training system of electrical control

"Semi physical simulation training system of electrical control" belongs to a part of cosai, which simulates electrical equipment, including high-speed servo motor, stepping motor, various CNC machine tools, grinder, general machine tools, overhead crane, various manufacturing automation stereoscopic warehouse, processing order station, etc. Provide hardware in the loop simulation interfaces, which support low-speed and high-speed simulation interfaces. It is connected with real distribution cabinet, single chip microcomputer, PLC, PAC, etc. to realize distribution teaching, embedded teaching, PLC and other controller teaching.

D4、Industrial automation digital twin platform

Digital twin platform (support the combination, layout, modification of operation parameters and other object engines of large-scale intelligent factory, fully compatible with the real controller's programming, debugging and monitoring controller engine, three-dimensional and two-dimensional VR driving engine, operation and equipment information display engine, and interface engine of management layer and cloud). Cosai & dtwins software supports object engine, controller engine, animation engine and display information engine. Thousands of simulation objects can be run at one time, and can be organized into factories, workshops, and workstations. It can run thousands of PLCs to control objects. It also supports offline project file mapping and online mapping. Support ERP, MEC, remote cloud connection.